Aluminum 6063 T5 or T6 is a commonly used material for door and window extrusion profiles. What’s the difference between the two?

6063-T5 VS 6063-T6

Aluminum alloy products can be broadly categorized into series 2, 3, 4, 5, 6, 7, and 8. The 6000 series is commonly used for aluminum door and window profiles. This refers to aluminum alloys with magnesium and silicon as primary elements and Mg2Si as the primary strengthening phase.

Whether aluminum 6063 T5 or T6 is determined primarily by the heat treatment process; for example, 6063-T5 and 6063-T6, the first digit, 6, indicates that the product is a 6-series alloy, while the last two digits distinguish different alloying contents within the same group. The biggest difference between T5 and T6 lies in the heat treatment process: T5 is formed at high temperature, while T6 is solution heat treated. The specific difference is reflected in the mechanical properties and hardness values under different conditions. In terms of tensile, compressive, and flexural design values, as well as hardness, 6063-T6 aluminum alloy extrusions are slightly higher than 6063-T5.

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Typical Hardness (HB) |

| 6063-T5 | ≈160–180 | ≈110–130 | 8–10 | 60–70 |

| 6063-T6 | ≈190–220 | ≈160–180 | 6–8 | 80–90 |

6063 T5 VS 6063 T6: Application Differences

6063-T5 aluminum profiles are suitable for low-rise buildings under 6 stories and ordinary residential doors and windows (such as bedroom casement windows and kitchen sliding windows). T5’s strength meets daily needs.

6063-T6 aluminum profiles are suitable for high-rise buildings and floor-to-ceiling windows, office curtain wall windows, and homes in coastal and windy areas. T6’s high strength and weather resistance ensure the stability of doors and windows, preventing deformation, falling, and salt spray corrosion.

How to Choose the Right Aluminum Door and Window Profiles

Generally speaking, aluminum alloy window profiles are mainly affected by Wall thickness. In areas subject to high loads, the wall thickness should be no less than 1.4mm. Doors and windows on higher floors can be appropriately thickened to 1.8mm. Furthermore, if a single door or window exceeds 3-4 square meters, additional thickness may be applied. Excessively large windows can also be thickened to increase stability and wind resistance.

Thus, doors and windows requiring a wall thickness of 2.0mm or greater generally include narrow-sided sliding doors, balcony sliding doors, and balcony and bedroom windows that frequently face strong winds and heavy rain.

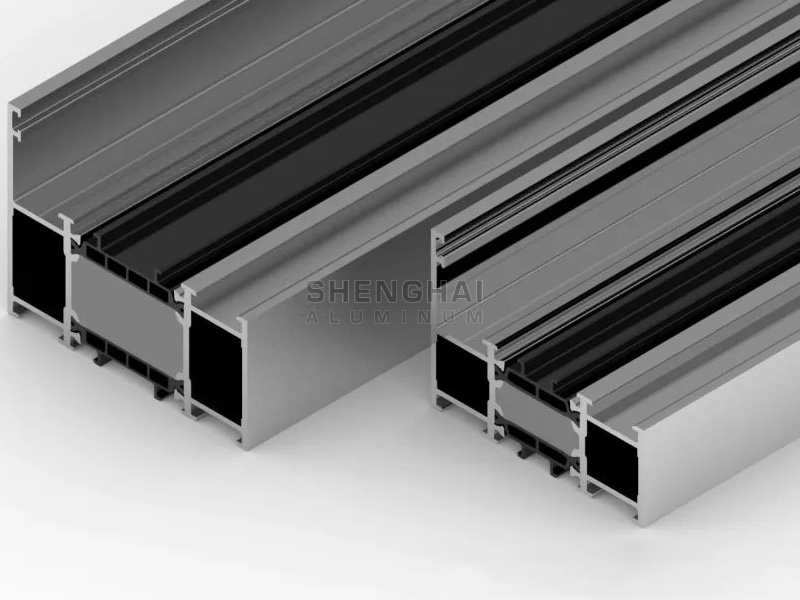

In general, when choosing aluminum door and window profiles, choose 6063 T5 or 6063 T6 depending on the project and application. Shenghai Aluminum is a professional aluminum door and window profile manufacturer. Contact us today for professional solutions.