Aluminum Bi-folding Doors are a type of folding door that folds to both sides, typically consisting of two or more door panels, greatly saving space. Bi-folding doors come in various materials, such as aluminum, wood, plastic, and stainless steel, with aluminum bi-folding doors being one of the most common types. What are the best aluminum bi-folding doors? The following guide will provide a guide.

Why Choose Aluminum Bi-folding Doors?

Aluminum doors are widely used in many places and are prevalent in various countries and regions. Why choose aluminum as the door material instead of other materials? Clearly, it’s because the properties of aluminum profiles are more suitable for making bi-folding doors.

High Strength

One of the main characteristics of aluminum profiles as the material for aluminum bi-folding doors is their strength. Alloyed aluminum profiles possess a strength comparable to steel, effectively resisting typhoons, external impacts, and more. Compared to wooden and plastic doors, aluminum doors are exceptionally sturdy. Furthermore, glass doors are becoming increasingly popular, and their construction requires robust materials like aluminum profiles to support their weight.

Corrosion Resistance

Aluminum bi-folding doors offer the strongest corrosion resistance. Doors made of aluminum can last for decades without corrosion, a key reason why aluminum is used in door construction.

Aesthetically pleasing and available in diverse colors

Due to the surface treatment processes of aluminum profiles, a variety of attractive colors are available, such as metallic, wood grain, and traditional colors. It can completely replace the natural wood grain style of wooden doors and offers countless metallic color options, making aluminum profiles a top choice for door materials.

Environmentally friendly

The environmental performance of aluminum profiles is unmatched by other materials. The extrusion process of aluminum profiles produces almost no harmful materials. Furthermore, aluminum has a recycling rate of up to 90%, maintaining a high recycling rate even after many years of use, complying with environmental policies—a characteristic not found in wood, plastic, and other metal materials.

Faqs

Pure aluminum isn’t particularly strong, but aluminum alloys (such as 6061 and 6063) are several times stronger. These alloys incorporate elements like silicon (Si), copper (Cu), and magnesium (Mg) to enhance their hardness. The extrusion process also further strengthens the aluminum alloy.

Aluminum doors are typically made of aluminum alloy and glass. One reason for their corrosion resistance is the inclusion of various corrosion-resistant metallic elements in the aluminum alloy frame, which enhances the alloy’s inherent corrosion resistance. Secondly, the natural oxide film on aluminum alloys is crucial. Aluminum alloys can quickly form a dense oxide film with oxygen to protect themselves from corrosion. Surface treatment further enhances the corrosion resistance of aluminum door frames, making it the most important factor in aluminum’s corrosion resistance. Finally, glass door panels are inherently highly chemically stable inorganic materials, maintaining excellent corrosion resistance without extensive treatment.

Because the extrusion process produces virtually no waste or waste liquid, and aluminum doors can maintain a high recycling rate of up to 90% even after decades of use.

Material selection when purchasing Aluminum Bi-folding Doors

Aluminum folding doors are mainly composed of aluminum alloy frames and glass.

Aluminum Alloy Frame

Aluminum Alloy: 6063 is a commonly used aluminum alloy door frame material, considered the best choice in terms of hardness, corrosion resistance, and price.

1.Surface Treatment: Surface treatment is generally chosen based on the environment. Powder coating is the most common method, ideal for home environments such as balconies, living rooms, kitchens, and bathrooms. It’s also one of the most cost-effective processes. Anodizing produces a thick, high-hardness oxide film, suitable for areas prone to wear and tear, such as public places and industrial sites. Fluorocarbon coating is generally used in areas with strong ultraviolet radiation or high salinity, such as coastal areas.

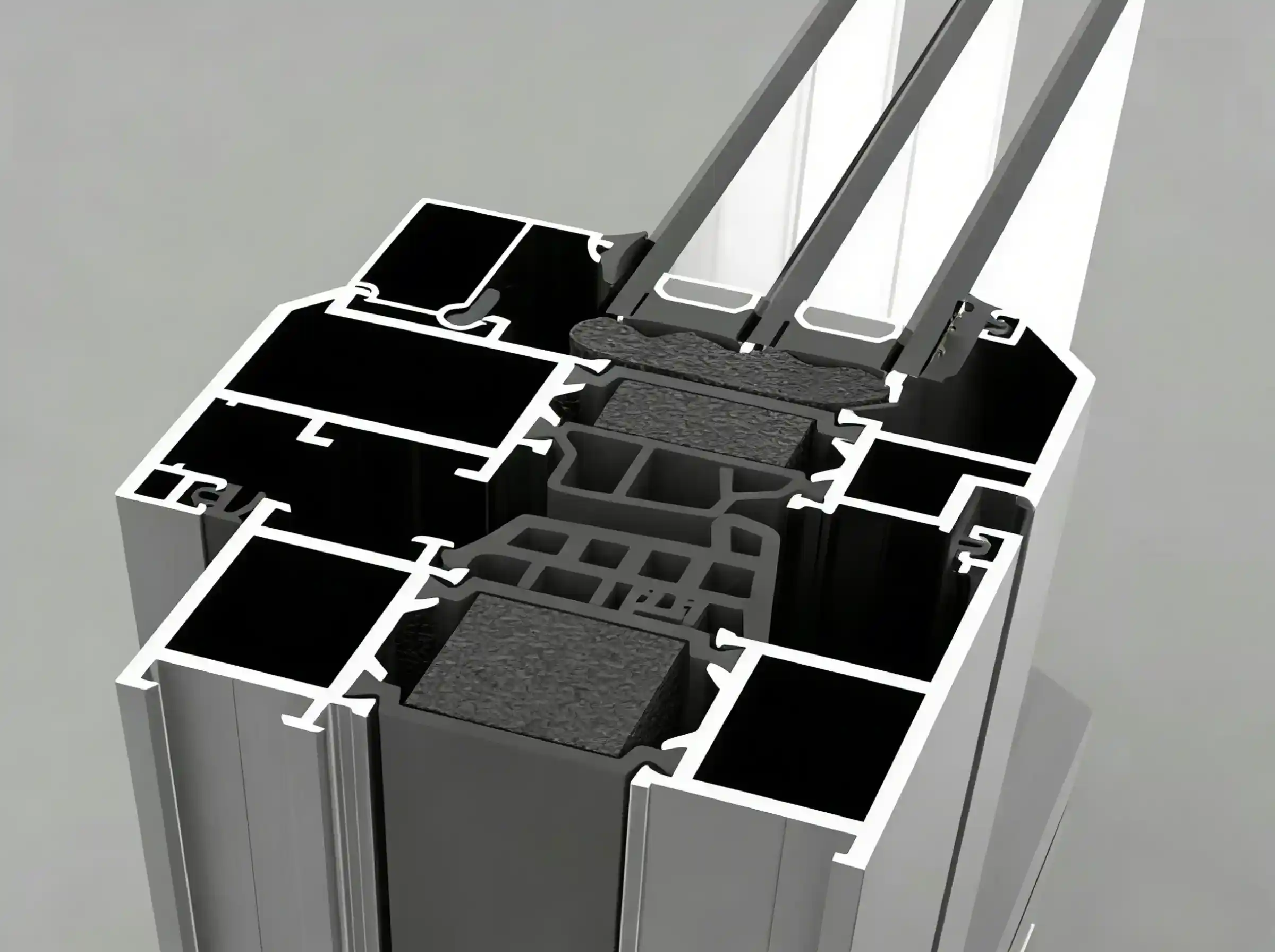

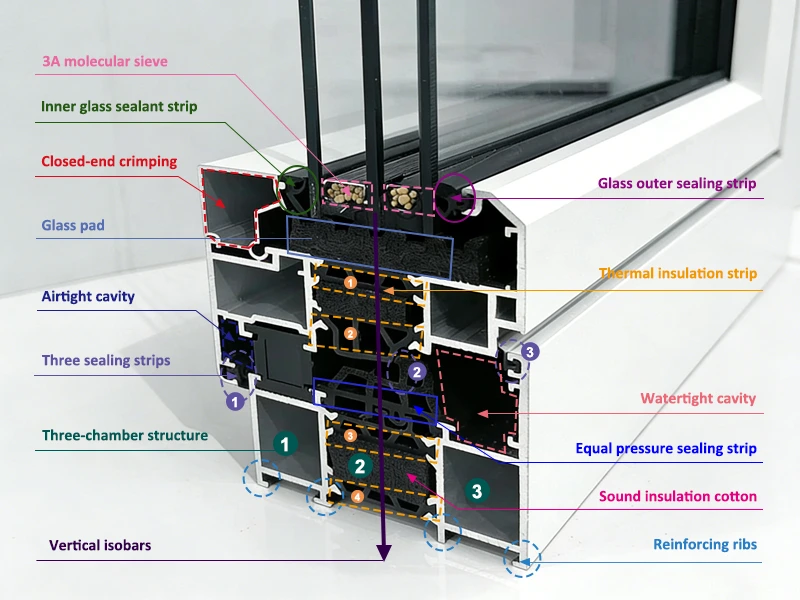

2.Structure: Using thermally broken aluminum alloy significantly enhances the door’s strength and lifespan. This structure increases durability and reduces maintenance costs. Therefore, when choosing an aluminum alloy door frame, confirm whether it features a thermally broken design.

Glass

Tempered glass is the preferred choice, a widely used material that ensures door strength and prevents injury from breakage.

To minimize heat transfer in winter and summer, the glass structure uses a double-glazed design. The hollow design not only provides insulation but also reduces noise and provides soundproofing.

You will also like

Prices of Aluminum Bi-folding Doors

Standard Aluminum Bi-folding Doors: 600-900 RMB

Mid-range Aluminum Bi-folding Doors: 900-1200 RMB

High-end Aluminum Bi-folding Doors: Over 1200

RMBThese prices are for the Chinese market in 2025. China is a major aluminum producer globally, and prices are relatively competitive. Therefore, purchasing Aluminum Bi-folding Doors in China is a wise choice.

Shenghai Aluminum is one of the best Aluminum suppliers in China. Established for 15 years, we have continuously improved and become a trusted supplier for international customers. Our main products include aluminum doors, windows, furniture, and industrial aluminum. We offer aluminum door customized solutions and are a worthy choice.Please contact us