Today, let’s talk about the aluminum profiles used for doors and windows.

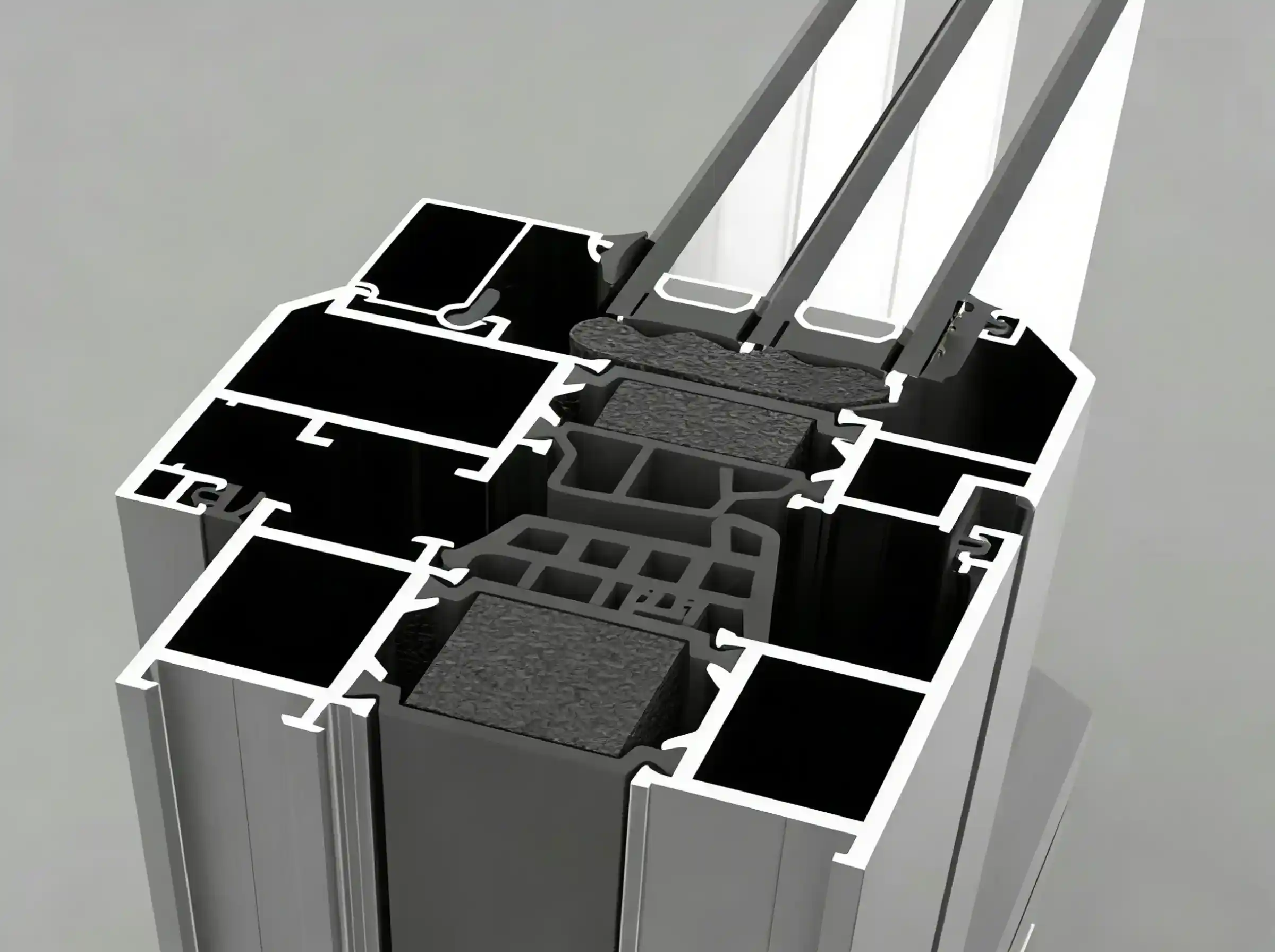

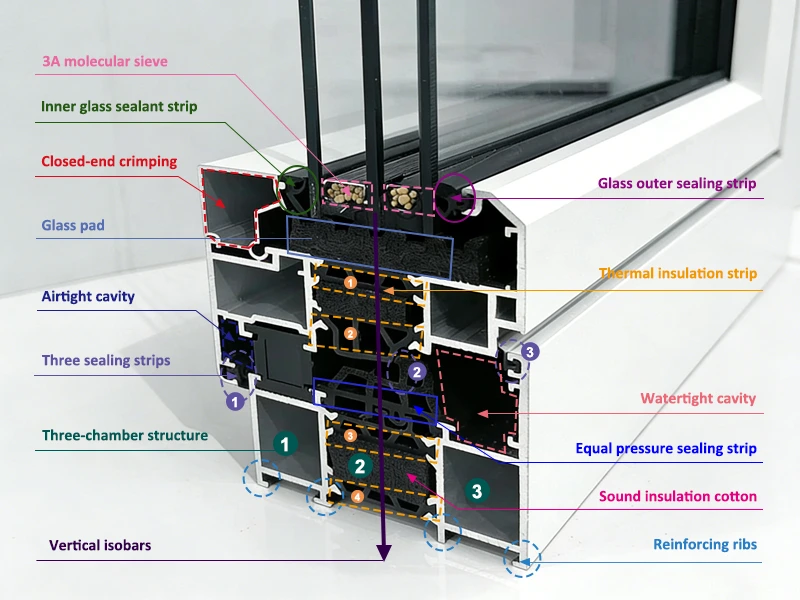

This aluminium profile is used to make the frames of aluminium alloy doors and windows, as well as for decorative construction materials. It is made of aluminium alloy and is installed at the doors and windows of buildings. It can serve both as decoration and as a frame. This thing is really impressive. It has strong wind resistance, high mechanical strength, excellent weather resistance, and is also a fire-resistant material. The aluminium profile industry in China has a complete production system.

In 2020, a national standard “Aluminium Alloy Doors and Windows” came into effect, raising the requirements for the wall thickness and surface treatment of the profiles. This has driven the entire industry towards the development of high-performance products. The mainstream products now include standard sliding windows, sliding windows, and insulation series. The insulation series uses multi-chamber design, significantly improving the insulation and soundproofing effects. The profile structure mainly consists of frame materials, sash materials, and center support rods, along with hardware accessories. With these, the functions of the doors and windows can be diverse. In terms of application, over 60% are used in the construction field. Why? Because aluminium-magnesium-silicon alloy (the 6 series) is corrosion-resistant and easy to process, so it has become the main base material.

Let’s talk about classification again

According to structure and function, the aluminum profiles used for doors and windows can be divided into these three categories:

Common sliding/rolling window series:

The base material wall thickness used in the past (before 2021) was 1.4 millimeters, and it was generally used on standard doors and windows in low-rise buildings.

Insulation bridge series:

It contains PA66 nylon insulation strips, which can separate the hot side and the cold side. The main profile wall thickness reaches 1.8 millimeters (this is the new standard in 2020), and the insulation performance has increased by 40% compared to before.

Facade series:

There are two frame configurations: exposed and concealed. The design of the profile cross-section must meet the requirements of wind pressure resistance and compression in building facades.