What is “Thermal Break Aluminum”?

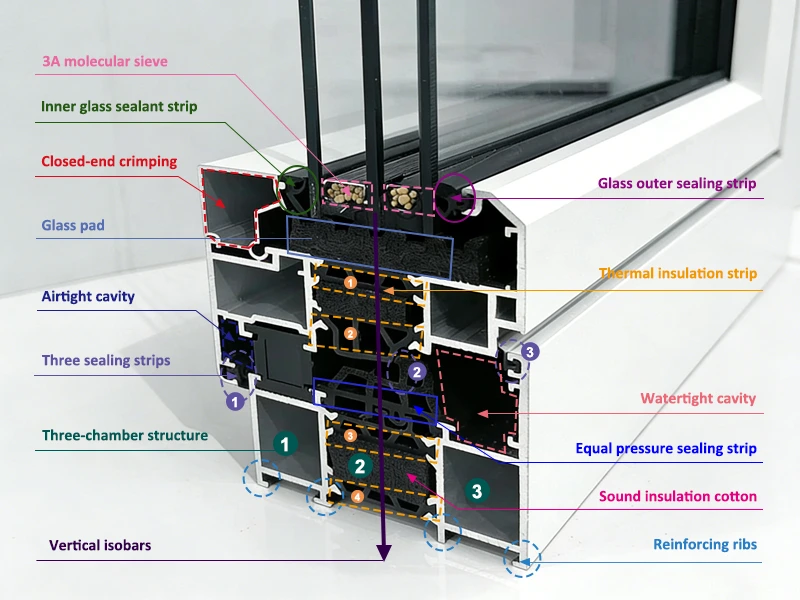

Aluminum alloys have high thermal conductivity. Therefore, when making thermal break aluminum windows and doors, “thermal bridges” are easily formed within the frame, allowing for easy transfer of temperature between the inside and outside. To prevent the influence of external temperatures, filling the aluminum frame with insulating thermal materials creates a “thermal break,” significantly reducing heat transfer and maintaining the indoor temperature within a comfortable range.

How Thermal Break Aluminum Windows and Doors Work

Frame Insulation: After adding insulating material to the aluminum window and door frame, there is an extra layer of insulation between the metal layers of the frame. Heat transfer between the inside and outside then occurs through aluminum alloy – insulation strip – aluminum alloy, significantly reducing heat transfer.

Double Glazing Reduces Air Convection: The air layer in double-glazed glass reduces air convection, ensuring warmth indoors.

Features of Thermal Break Aluminum

Thermal Insulation

The double-glazed glass and thermal break aluminum frame design of the windows and doors significantly reduces heat transfer. This is one of the biggest features of thermal break aluminum windows and doors, and one of the reasons why many people choose them.

Sturdy Structure

The windows and doors are designed with structural sturdiness in mind. The combination of the frame and glass can withstand even a Category 12 typhoon, and it also has strong anti-theft capabilities.

Sound Insulation

The sound insulation effect of the windows and doors is also one of the main features of thermal break aluminum. Even in bustling cities, next to roads and subways, it maintains excellent sound insulation, making it popular with people who value quiet.

Sealing, Waterproofing, and Windproof

Its windproof and waterproof properties are due to the sealing effect and drainage system of the thermal break aluminum. Even during heavy storms, it can prevent wind and rain from entering the interior, ensuring indoor comfort.

Aesthetically Pleasing Appearance

Aluminum alloys offer over 2000 powder coating colors. Therefore, when choosing windows and doors, you can find a beautiful color that suits your needs. Whether it’s a metallic look, natural wood grain colors, or traditional colors, the surface treatment of aluminum alloy can meet your requirements.

What are the structural components of thermal break aluminum windows and doors?

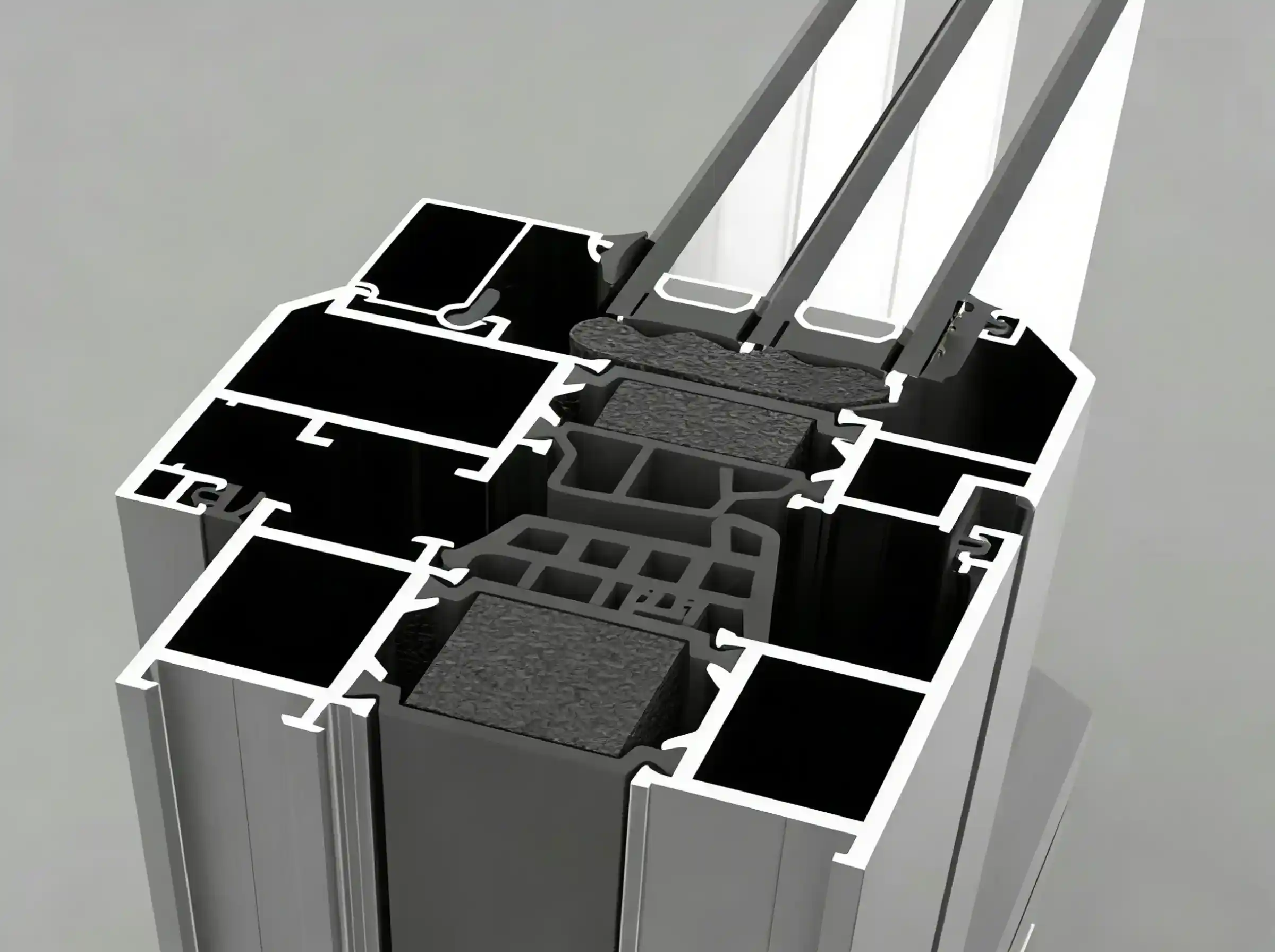

Aluminum alloy thermal break frame: Includes two layers of metal aluminum alloy, thermal insulation strips, and sealing strips.

Insulated glass: Double-layered glass, with an air layer in between, glass film, and sealing strips.

Drainage system: Rainwater interception layer, water collection and drainage slopes, drainage holes, and anti-backflow layer.

What are the differences between thermal break aluminum and standard aluminum window and door frames?

Thermal break aluminum windows and doors:

Appearance: More diverse appearance, thinner aluminum frames, distinct indoor and outdoor layers, and a wider range of surface treatment colors. To accommodate the insulated glass design, the glass is usually multi-layered.

Thermal insulation effect: The thermal insulation strips and insulated glass design of thermal break aluminum significantly reduce heat transfer between the interior and exterior, reducing the cost of maintaining indoor temperature.

Wind and water resistance: The multi-chamber reinforced design can withstand Category 8 typhoons, and good windows and doors can even withstand Category 10 typhoons. Due to the sealing strips and hidden drainage system of thermal break aluminum, there is no water leakage even during heavy rain. It’s worth noting that thermal break windows and doors also prevent condensation on indoor windows in winter.

Standard aluminum windows and doors:

Appearance: Fewer colors, generally single-layer glass, typically used in environments with less temperature difference between indoor and outdoor. The aluminum frame is thicker.

Thermal insulation effect: Standard aluminum windows and doors have a pure aluminum alloy frame and single-layer glass design, with no thermal insulation effect, and may even increase indoor temperature due to the high thermal conductivity of aluminum alloy.

Water and wind resistance: Weaker water and wind resistance, not suitable for environments with heavy rainfall and strong winds.

Examples of regions where thermal break aluminum windows and doors are widely used:

New Caledonia

New Caledonia is an overseas territory of France, with a tropical savanna climate. It is constantly exposed to high humidity, salt spray, and rainy weather. The corrosion resistance, high strength, and waterproof and windproof characteristics of thermal break aluminum alloy windows and doors are highly suitable for New Caledonia’s climate.

United Arab Emirates

The Middle East has a desert climate, with long periods of hot and sandy weather, leading people in the United Arab Emirates to take extensive measures to protect themselves from the sun. Aluminum alloy thermal break windows and doors are very suitable for people in the Arab region, as their design provides excellent thermal insulation and strong wind pressure resistance.

United States

The United States has a large temperature difference between the north and south, with the north being colder and the south experiencing hot weather. The advantage of aluminum alloy thermal break windows and doors is that they are suitable for these extreme temperatures, effectively regulating indoor temperature in both cold and hot weather, providing a comfortable environment for people.

Canada

Canada’s climate is generally characterized by severe cold and snowy weather, so indoor insulation is essential. The excellent insulation and robust structure of aluminum alloy thermal break windows and doors are well-known, providing a warm indoor environment for people in Canada.